Unlocking the Potential of Fused Deposition Modeling 3D Printing

Introduction

Welcome to QuickParts.com, your premier destination for all things related to Metal Fabricators and 3D Printing. In this article, we will explore the incredible potential of Fused Deposition Modeling (FDM) 3D printing technology and its various applications across industries. With our expertise and cutting-edge solutions, we aim to provide you with comprehensive insights into leveraging FDM technology.

The Power of Fused Deposition Modeling

FDM 3D printing, also known as Fused Filament Fabrication (FFF), is a widely used additive manufacturing process that offers a range of benefits for businesses across different sectors. This innovative technology utilizes a thermoplastic filament, typically made of materials like ABS or PLA, which is heated and extruded layer by layer to create intricate and precise 3D objects.

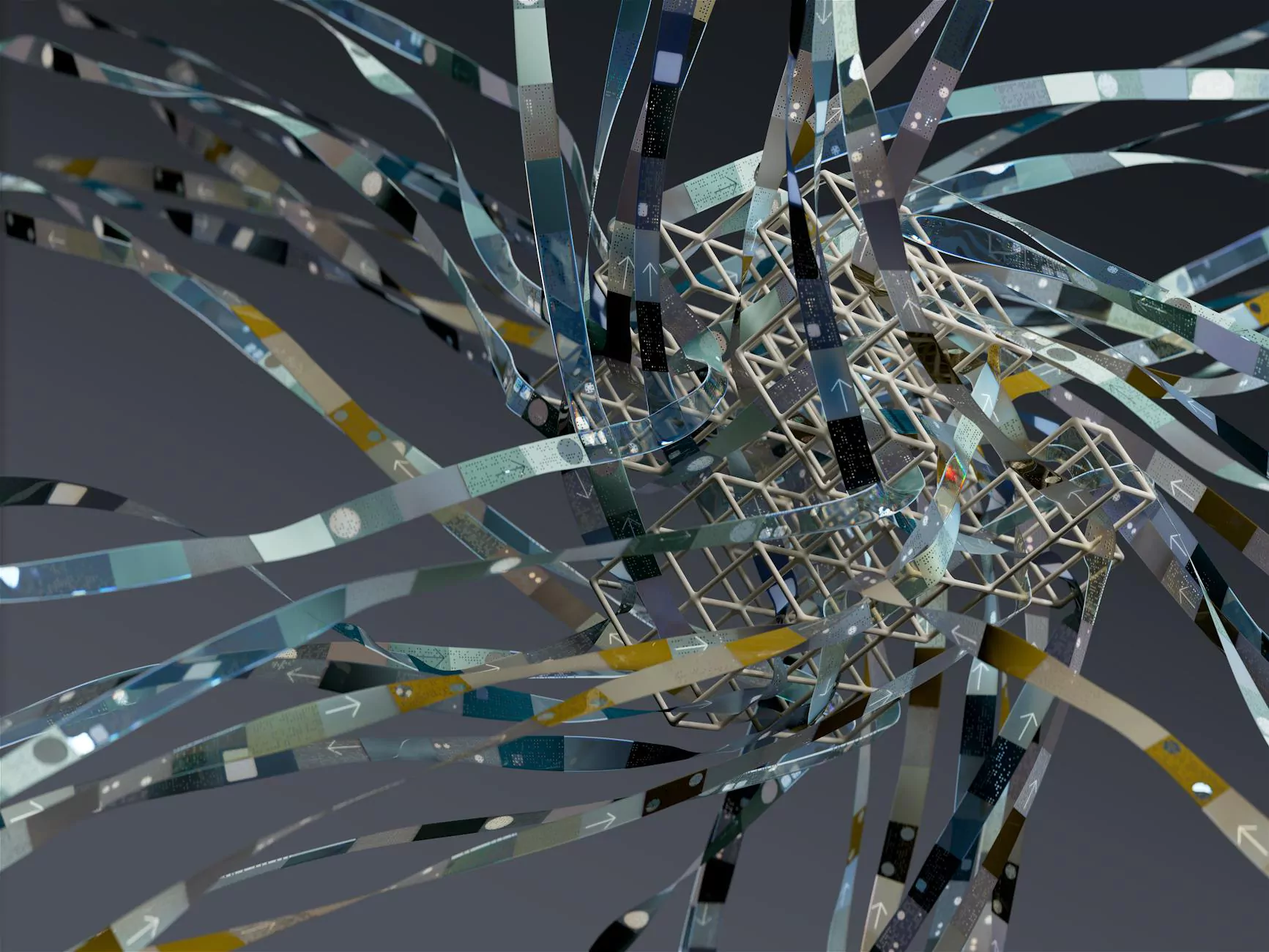

One of the major advantages of FDM 3D printing is its versatility. Whether you require functional prototypes, end-use parts, or even artistic creations, FDM technology can deliver outstanding results. Its ability to produce complex geometries and internal structures with ease makes it an ideal choice for product development, rapid prototyping, and even low-volume production.

The Applications of FDM 3D Printing

1. Rapid Prototyping

In the fast-paced world of product development, time is of the essence. FDM 3D printing enables businesses to rapidly iterate through design concepts, test functionality, and gather feedback from stakeholders before committing to expensive tooling and production. The accuracy and speed of FDM technology help reduce lead times, accelerate the innovation process, and ultimately bring products to market faster.

2. Customized Manufacturing

Personalization is a growing trend in various industries, ranging from consumer goods to healthcare. FDM 3D printing empowers businesses to offer unique, customized products to their customers. By leveraging the inherent flexibility of FDM technology, businesses can easily modify designs, incorporate personalized elements, and produce one-of-a-kind items, giving them a competitive edge in the market.

3. Tooling and Jigs

FDM 3D printing is revolutionizing the manufacturing landscape by enabling the production of customized tools and jigs. Traditional methods often involve significant time and cost investments for creating tooling, which can be a hindrance to agile production processes. With FDM technology, businesses can quickly design and fabricate tools tailored to their specific requirements, thereby streamlining production and improving overall efficiency.

4. Functional Prototypes

Validating the functionality and performance of a product is crucial in the development phase. FDM 3D printing allows businesses to create functional prototypes that closely mimic the properties of the final manufactured product. The ability to test and iterate designs with functional prototypes significantly reduces the risk of potential issues and ensures a smoother transition to mass production.

5. Low-Volume Production

When it comes to low-volume production, FDM 3D printing offers distinct advantages over traditional manufacturing techniques. With minimal setup costs and no need for tooling, FDM technology enables businesses to produce small batches of parts economically. This flexibility is particularly beneficial for niche markets, limited editions, and unique product lines.

Partner with QuickParts.com for Your FDM 3D Printing Needs

At QuickParts.com, we pride ourselves on being your trusted partner for Metal Fabricators and 3D Printing solutions. With our state-of-the-art FDM technology and experienced team, we are committed to delivering high-quality, precise, and functional parts for an array of applications. Whether you require prototyping, custom manufacturing, or low-volume production, we have the expertise and resources to meet your specific needs.

Unlock the potential of fused deposition modeling 3D printing with QuickParts.com. Contact us today to discuss your project requirements and explore how we can help you turn your ideas into reality.